Extraction and use of cold-pressed oil can be traced back to significant part of our history. The procedure however has changed and updated along the timeline.

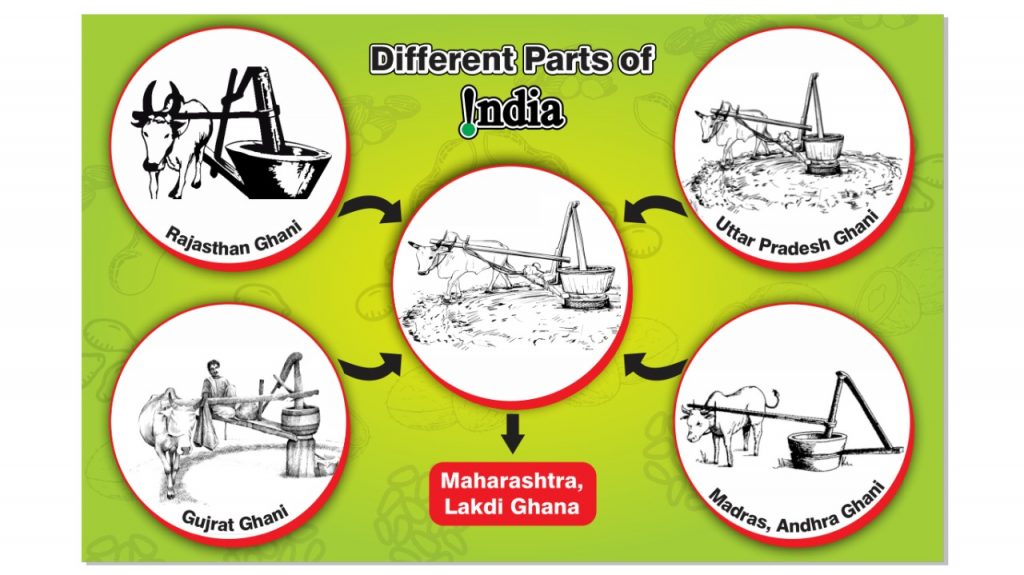

In old days people used animals to operate the huge sized mortar and pestle, and extract oil from seeds. These mortar and pestle together were named as ‘Chekku’, ‘Ghani’ and ‘Kolhu’. They were made up of wood so that it would absorb the heat produced during the crushing process which has the capacity to spoil nutrients present in the oil.

Today, people use machinery that are run on electricity but the procedure is still the same, with increased efficiency.

Raw materials that are used for extracting these oils are one and only, best quality seeds of various kinds. These seeds are put into the main container, also called as mortar, where they are crushed using only pressure and no heat and chemicals at all. This preserves the nutritional quality of the oil and this is what is makes the cold-pressed oil many times more nutritional than refined oils.

Once the seeds are ground enough to turn them into fine powder and later extract oil from them, the whole mixture is let to settle for a day so that all the solid particles from the mixture would settle and pure and clean oil could be separated from it easily.

The oil extracted from these seeds is already enough nutritious and pure that is doesn’t require any kind of chemical treatment. This oil is later separated and packed into fresh containers and are ready to be used by the consumers.

This oils’ shelf life is about 6 months from manufacturing and it can be used for various purposes and at various occasions.